Benefits of Multi-Skilling

Many Companies Suffer a Shortage of Multi-Skilled Maintenance Engineers

A survey conducted by the UK Commission for Employment and Skills (UKCES)’s Employer Skills continually highlights the shortage in skills across industries. Vehicles technicians, mechanics, electricians, metalworking production and maintenance fitters regularly take up the top positions, where the highest percentage of skills shortages are.

Understanding the importance of multi-skilling your engineers is the first step towards addressing any skills shortages you may have.

Where did multi-skilling start?

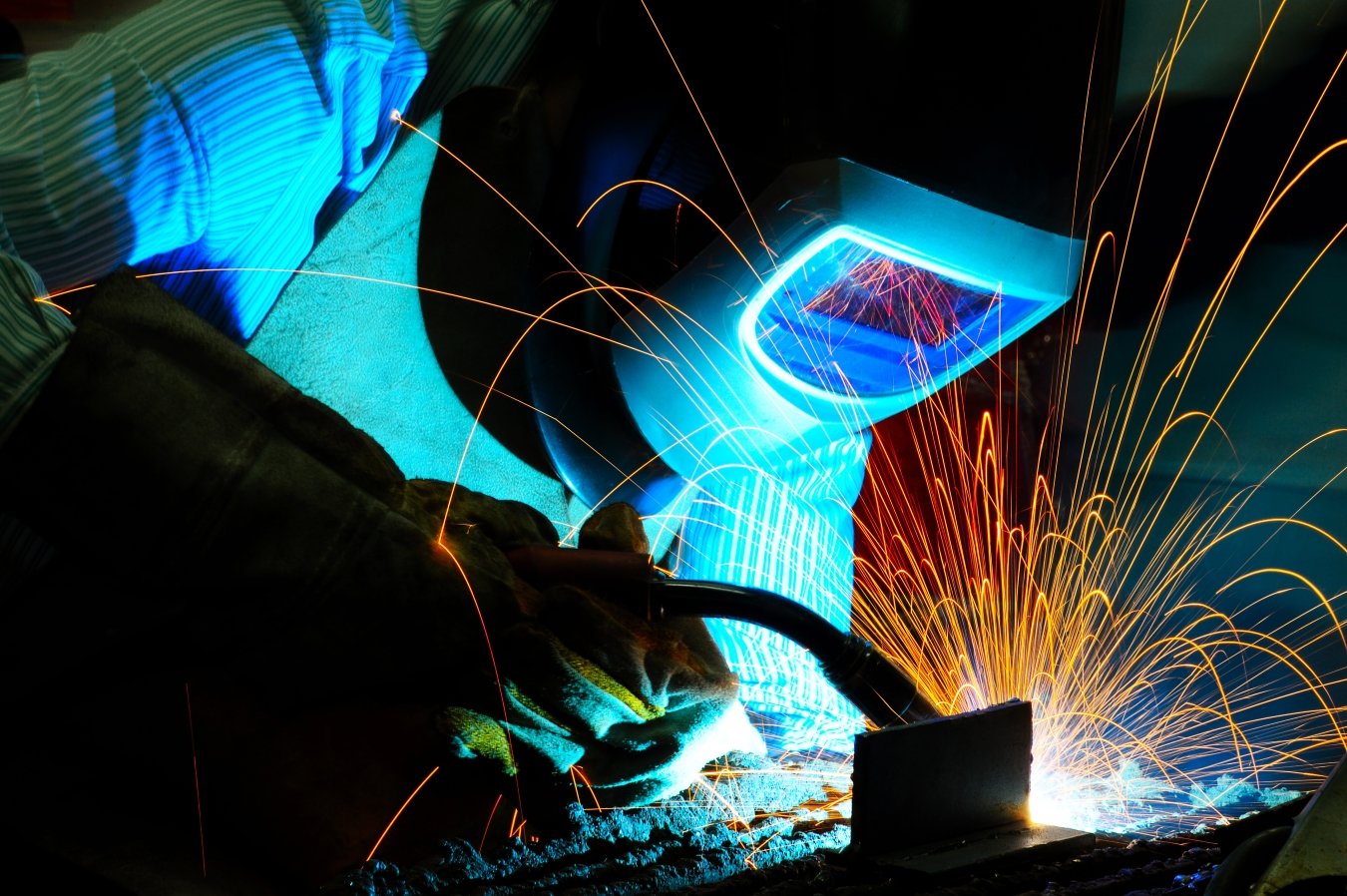

Multi-skilling started in the automotive industry. There was a need to keep the assembly line going so mechanical fitters were trained in high-frequency low-risk electrical tasks so that the fitter did not need to wait for an electrician to isolate and disconnect the motor before the fitter changed the gearbox.

In the water industry, some providers went a stage further by giving the mechanical fitters electrical and instrumentation skills. Why have three vans at an outlying pumping station when a single multi-skilled technician could complete most of the day-to-day tasks?

The benefit of the breadth of skills

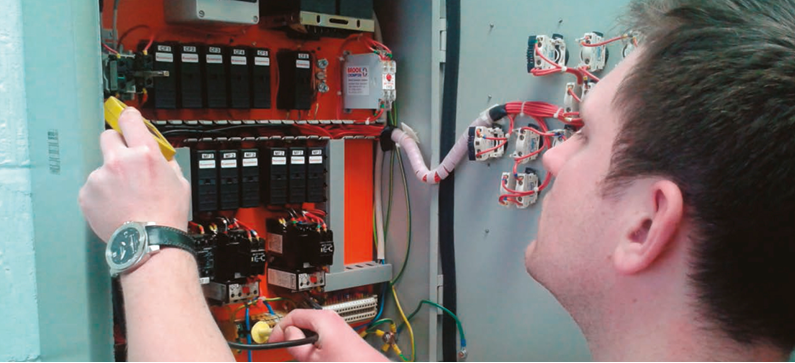

Companies today should now be interested in the breadth of skills rather than the depth of skills. No longer does the electrician rewind a motor in the workshop. In 2015 it is far more likely that the motor is scrapped or sent to a contractor to refurbish. The multi-skilled technician’s role is to maximise the up-time of the asset. This involves fault diagnosis, remedial work and then root cause analysis to prevent the fault reoccurring.

Focused training, particularly that aimed at multi-skilling of maintenance staff, can be a powerful force in addressing current skills shortages.

Some of the benefits of multi-skilling include:

Motivation and development of staff

Improved staff retention

Formal targeted training with direction and end focused on business need

Encouragement of teamwork through coach and assessor communicating more with opposite trade

Refocused training budget

Standard Operating Procedures (SOPs) and training packages are written around business need

Safe job; Timely job; Right first-time job

Improved productivity as downtime is reduced due to increased skills base

Cross cover of skills in event of absenteeism, sickness, etc

Nationally recognised qualifications where appropriate; skills are validated

Training records meet and exceed those required by HSE etc

Fulfills requirements of Investors in People

The government wants to see competence at work

Transforming the manufacturing business model through a multi-skilling training programme

Technical and management skills training are the best investment to make in your business. A business should never stand still and staff development is a key asset to drive the business forward. The benefits of ongoing workforce development will improve more than just your bottom line.

Fast-changing regulations, rapidly advancing technology and customer aspirations, mean that it is essential to keep staff up to speed with developments in technology, standards and regulation. By providing robust training staff will be more motivated, skilful, knowledgeable and productive.