Calibration! Calibration! Calibration!

Musing of a MAMIL

by John Saysell (Director of Technical Training) and friends!

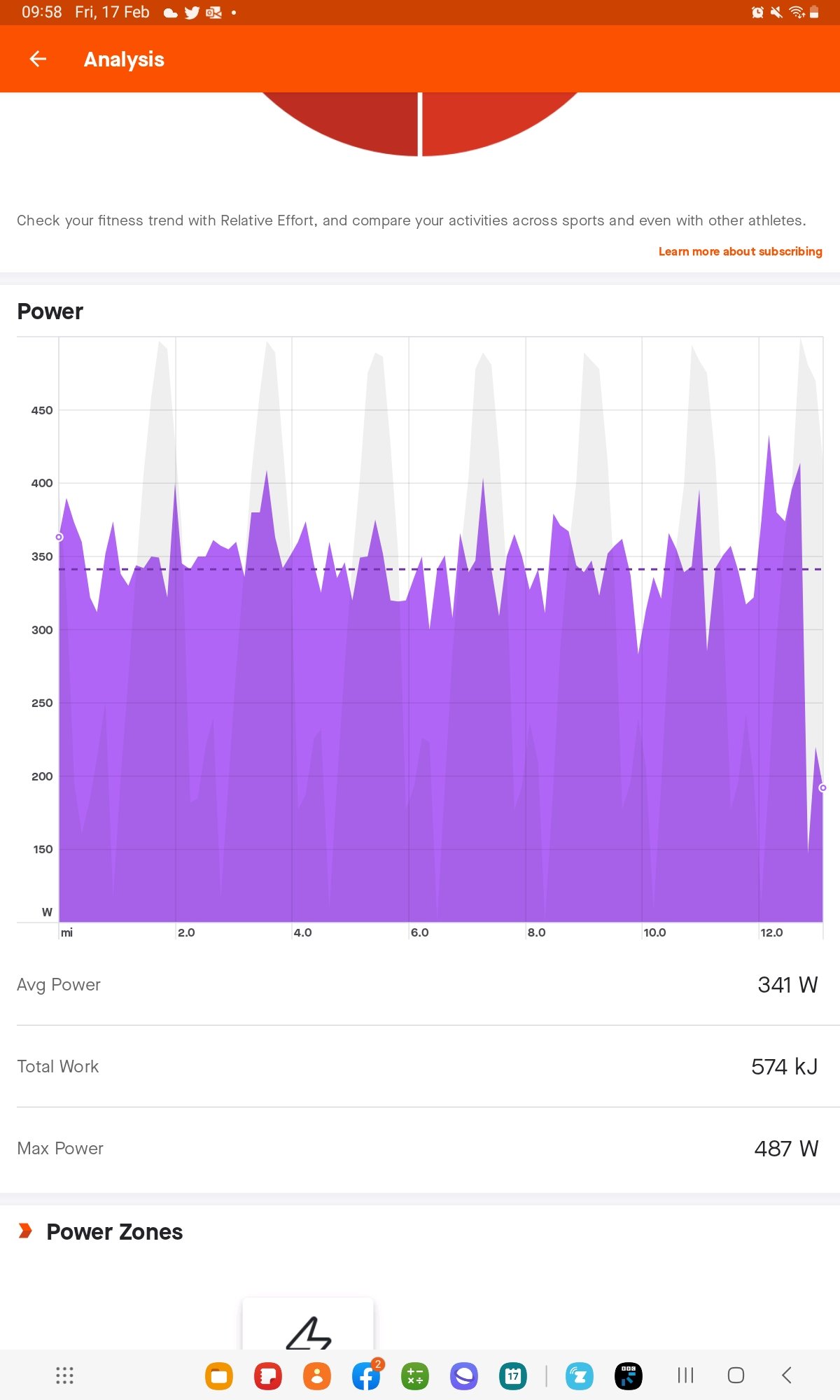

I bought a new power meter for my bike recently. Lo and behold - I am now producing 10% more power! This is great for my ego and performing in on-line cycling games like #Zwift, but what is the true power output? Is the old power meter right? Or the new one? Or is it somewhere in between? It doesn’t really matter as long as I go faster in time trials, later on in the year.

Calibration Matters

But in industry, calibration really does matter. If your gauges and metering devices are not calibrated correctly, you could be:

Endangering your staff

Increasing your maintenance costs

Decreasing the shelf life of work in progress and finished product

Giving away too much product

Using too much power

Contravening regulations

Short changing customers

Control & Instrumentation Training Rig

Training in Solihull

Practical Assignment

Internal Calibrations

We will outsource some of our calibrations, where external certification is required, but who is doing your internal calibrations?

Have you tried to recruit an instrument technician recently?

Is it worth upskilling your existing maintenance technicians to enable them to assist?

City & Guilds Accredited

MCP has a City & Guilds Accredited, Control and Instrumentation course. For more details follow the link below: