When Did You Last Review Your Electrical Procedures

When was the last time you took a close look at your electrical procedures?

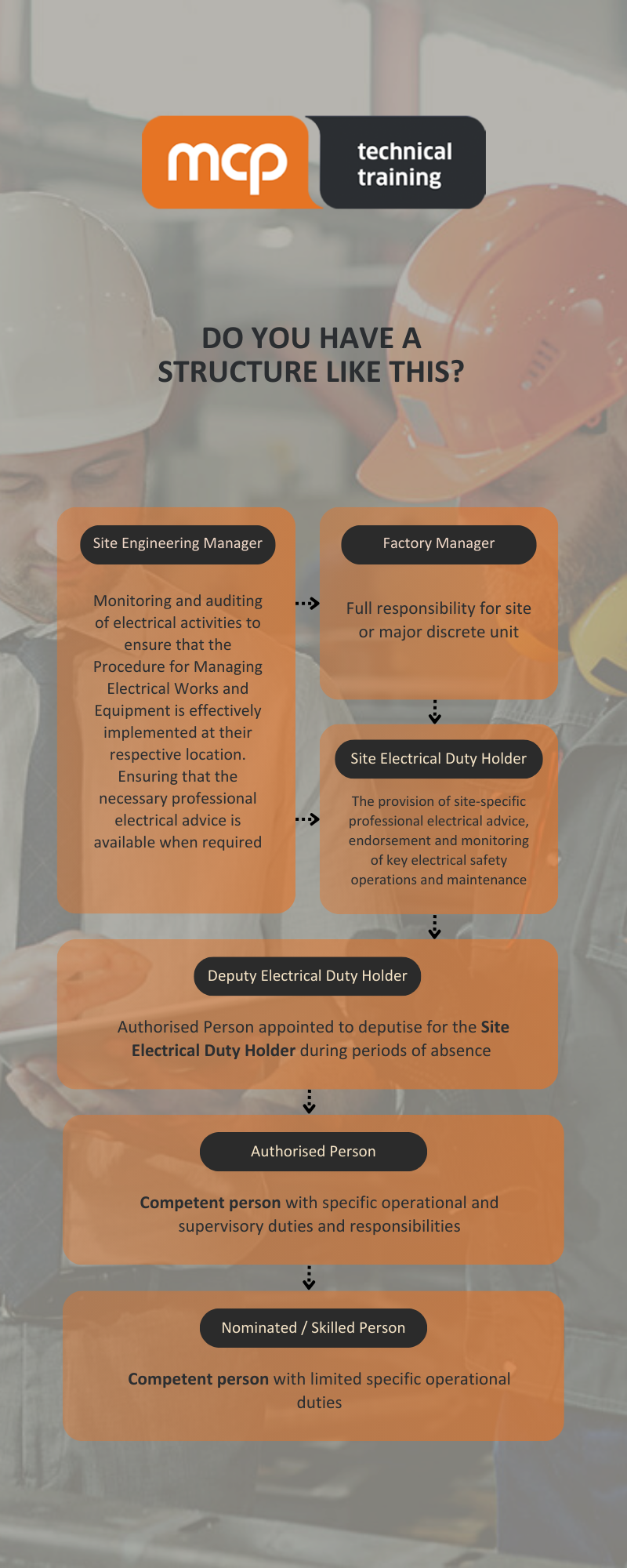

If you’re an engineering manager, chances are, there’s a well-thumbed binder on your shelf—a comprehensive guide to safety protocols and best practices with origins that might trace all the way back to the Ministry of Defence. But let’s be real—are those procedures still up to date, and, more importantly, are they being used??

In recent years, we’ve worked with companies across industries - from breweries to food manufacturers and airports to facilities teams, helping them take a fresh look at their safety standards. Here’s how we support organisations in modernising their electrical procedures, training, and safety compliance.

Key Steps in Refreshing Electrical Procedures

1. On-Site and Off-Site Sense-Checking

Our team starts by giving your procedures a thorough review, in the workplace, with the technicians, to see what the actually do. Think of it as a strategic health check—only, instead of diagnosing cholesterol, we’re diagnosing outdated practices. Our goal is to ensure that each procedure is clear, relevant, and safe by today’s standards.

2. Gap Analysis Against Best Practice

We’re all about alignment with best practices, so we assess where current protocols might fall short. If there’s a gap between the way your team operates and a better way, we’ll make sure you know exactly where it is—and what to do about it.

3. Procedure Rewrites

Sometimes, a quick edit isn’t enough. We take on the heavy lifting of revising and updating your procedures to create documents that meet the latest safety and operational requirements, ensuring your team is working with the best information available. We discuss with the stakeholders at all levels to ensure that everyone’s voice is heard.

4. Tailored Training Sessions and Courses

Once your procedures are up to date, it’s time to bring your team up to speed. We design training sessions that are easy to follow and engaging, helping to reinforce the importance of safety and practical adherence to new standards.

5. Train-the-Trainer Materials

Safety protocols should be accessible to everyone, especially as teams evolve. We create comprehensive train-the-trainer materials, so your current experts can impart crucial knowledge to new hires and refresher courses can be easily rolled out.

Do you have a recommended equipment list for electrical work?

Our approach to electrical procedures includes a range of key documents designed to streamline and standardise safety measures. Some of these include:

Control of Electricity at Work Policy

Management of Electrical Works, Systems, and Equipment Procedures

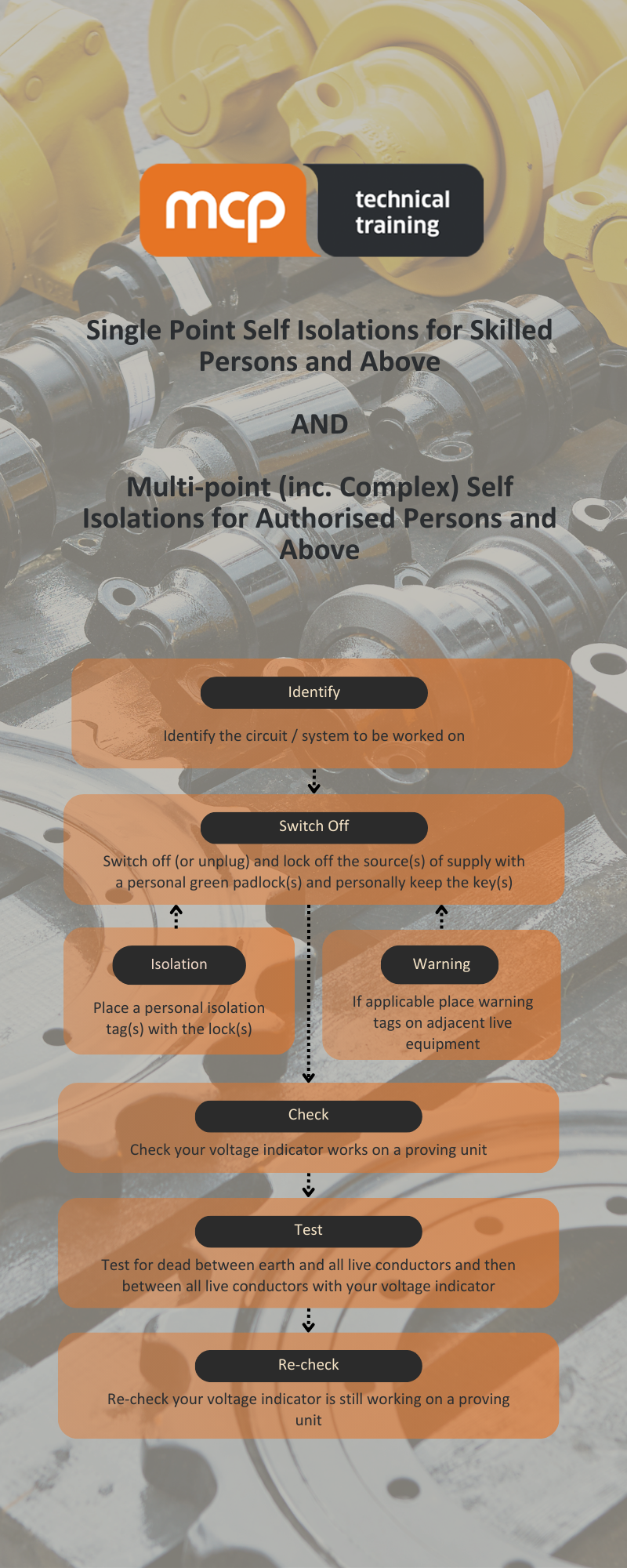

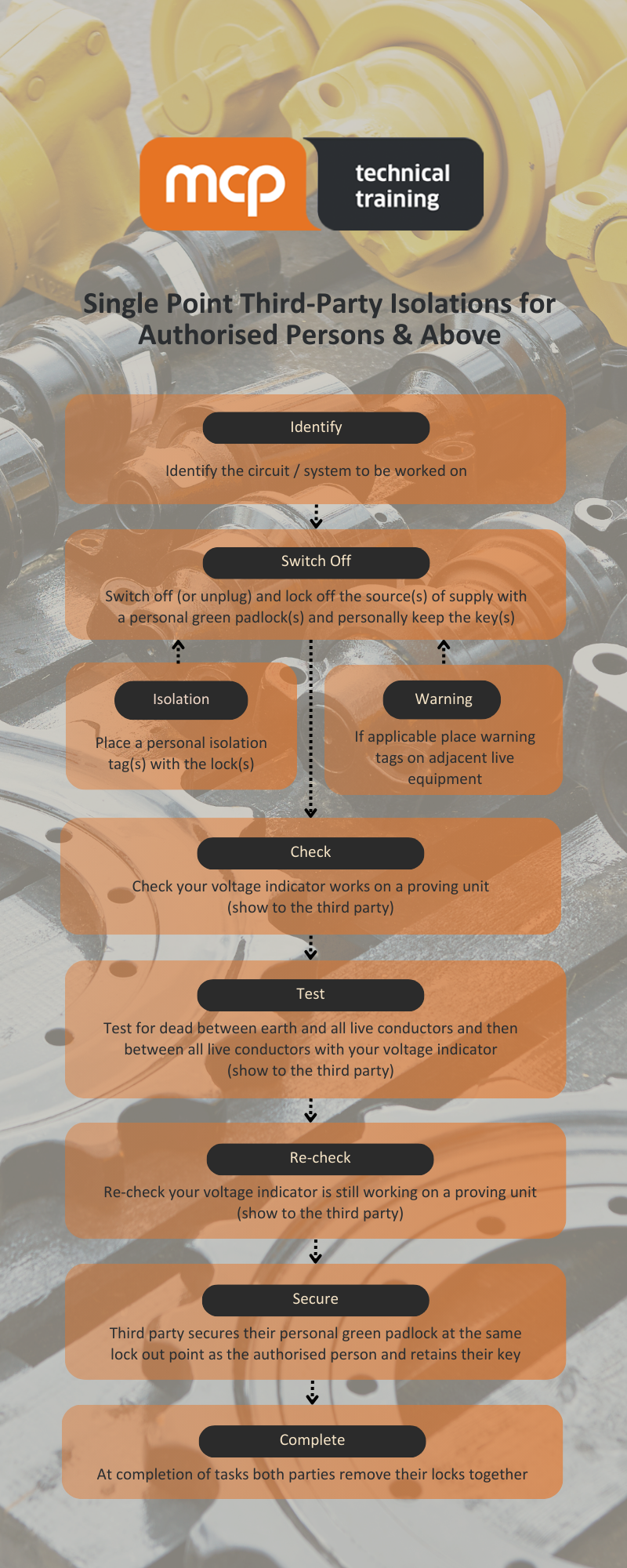

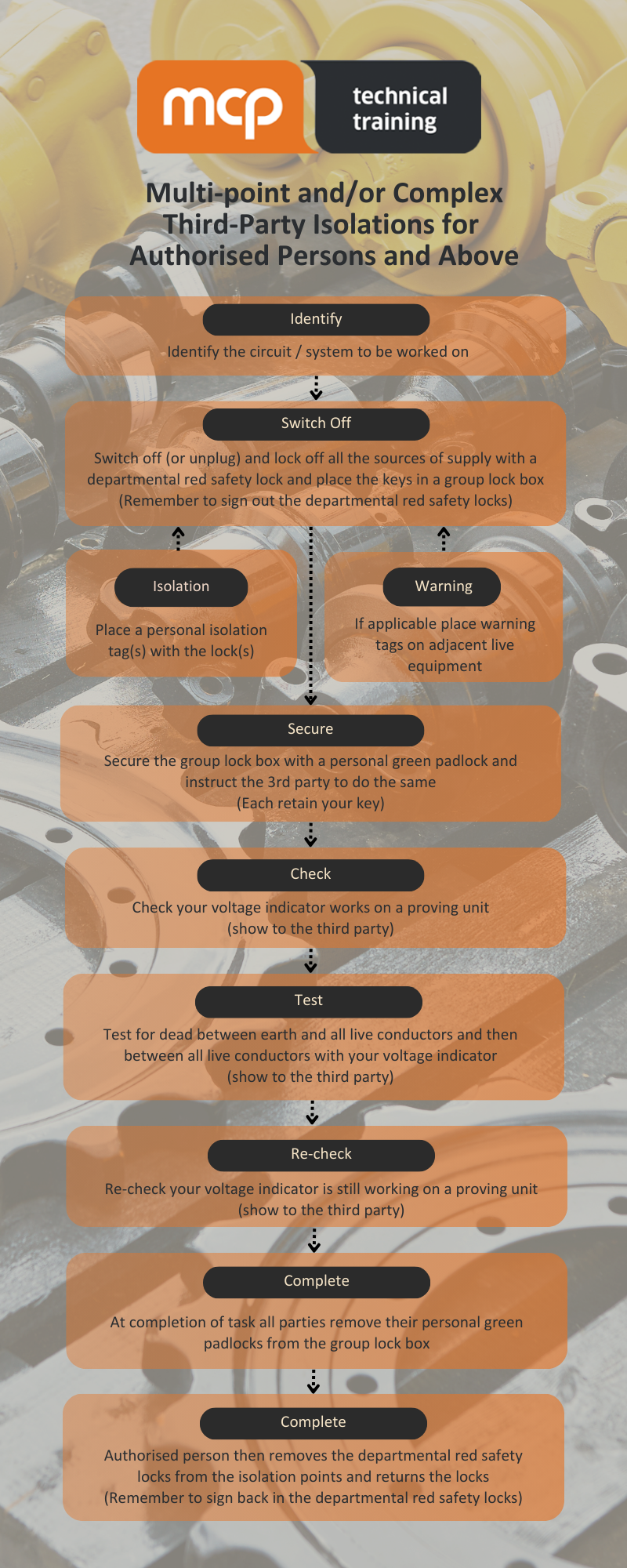

Electrical Isolation and Proving Dead Protocols

Specifications for Electrical Test Equipment

Permit to Work and Contractor Control Policies

And for organisations that need more, like an Engineering Services Process Handbook, including maintenance planning and scheduling, reliability, spares etc (we recently developed one for one of the world’s busiest airports), we’re prepared to go above and beyond.

Proof of why we need procedures and training

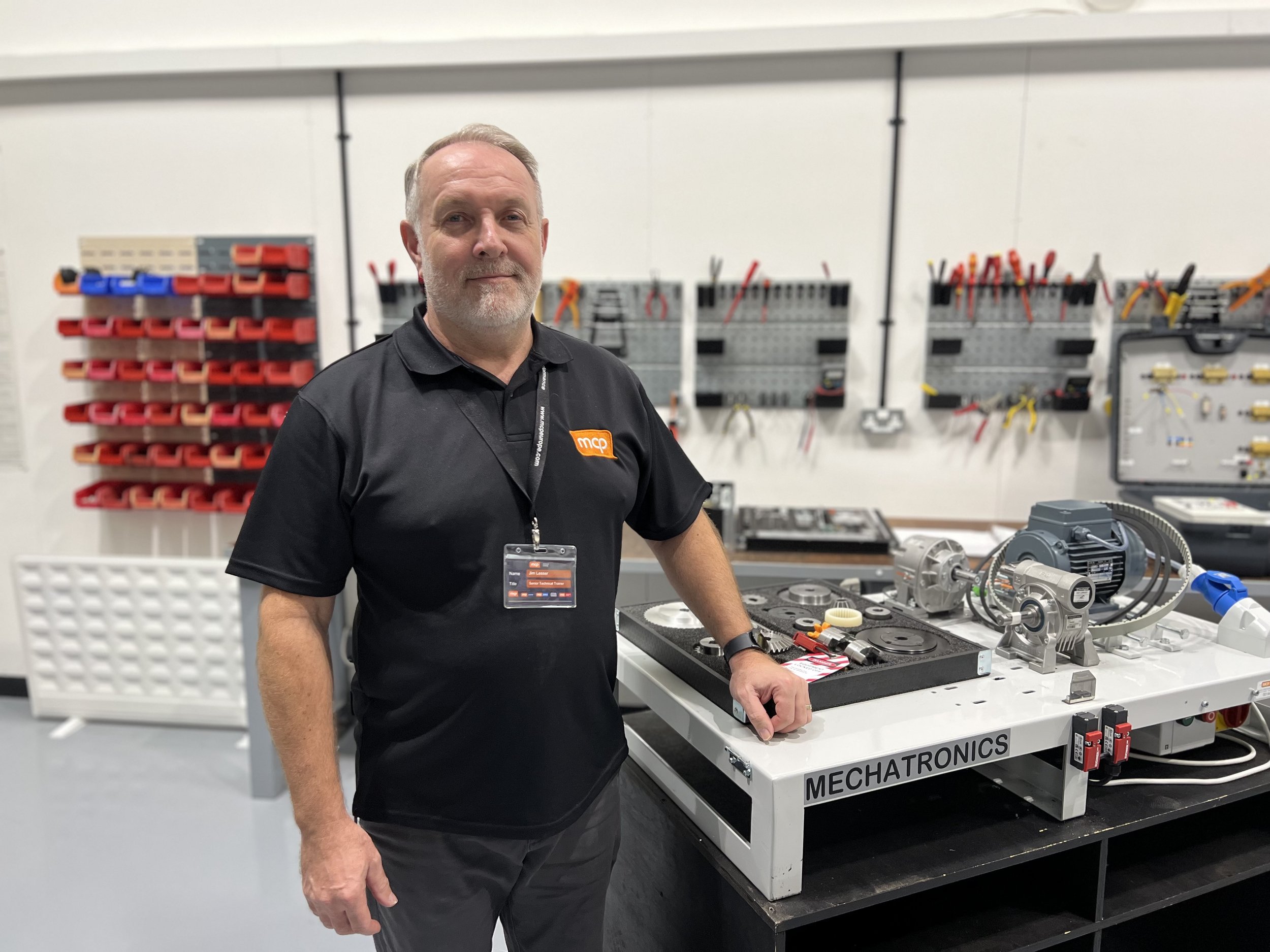

In our Maintenance Development Centres, we offer a suite of hands-on practical tasks, including electrical isolation exercises. Astonishingly, only about 25% of the staff we assess can complete a safe isolation correctly on the first try. For those other 75%, our training provides the critical skills and confidence needed to handle electrical procedures safely.

Ready to Modernise Your Procedures?

If your procedures need a refresh, we’re here to help. Reach out to MCP Technical Training for support with your engineering processes, electrical procedures, and safe isolation standards. Together, we’ll transform those aging documents into dynamic, effective tools that keep your team safe and compliant.