Other Electrical Training Courses

We have been providing our clients with bespoke electrical skills training for over 30 years

Other Electrical Training Courses

With City & Guilds, IAM and EAL accreditations, our name is well-respected in the market and is a trusted resource for companies wanting to up-skill their electrical biased workforce. By conducting electrical training in-house, you have the ability to train staff in an environment in which they feel comfortable. The electrical training courses on offer can be tailored to meet your exact requirements.

Our bespoke electrical training courses are best suited to groups of up to 10 members of staff, and are only conducted by expert trainers and consultants in their field, ensuring your team gain the most knowledge out of each session.

The following are examples of standard and bespoke electrical skills training courses we have provided our customers at their premises:

18th Edition Update

This one day training course will familiarise your technicians with the layout, content and application of BS 7671: 18 (2382-18) 18th Edition Wiring Regulations. The course focuses on the changes to the 18th Edition Regulations since the 17th Edition Amendment 3 update. It is entirely theory based and is completed by way of a multiple-choice open book assessment.

Portable Appliance Training (PAT)

On successful completion of the Portable Appliance Testing (PAT) course, delegates will have passed a range of practical competence assessments and a written assessment covering knowledge and understanding. This will enable the delegates to carry out PAT testing competently and safely.

Electricity at Work Regulations

The Electricity at Work Regulations affect every kind of employment in the U.K. including in factories, offices, shops, warehouses, colleges and hospitals. They place the responsibility on the employer to assess the work activities which use electricity, or which may be affected by it and define all foreseeable risks associated with these activities.

Employees have a duty to work in a safe manner and report all defects and unsafe practices. This training course draws attention to each aspect of the Regulations and explains how the requirements can be met and greater electrical safety achieved.

Control Panel Safe Access

The Control Panel Safe Access Workshop enables staff, with no electrical background, to safely rest an overload in a panel.

Delegates will be introduced to electrical concepts, such as voltage, current and resistance. They will be provided with an overview of The Electricity at Work Regulations and taught the dangers of electricity, AC/DC voltage levels and the procedure to adopt if somebody receives an electric shock.

There are practical exercises in component recognition and how to reset an overload in an electrical panel.

Electrical Duty Holder

An Electrical Duty Holder is a person appointed by the business with responsibility for the maintenance of the overall standard and quality of the electrical work undertaken within an organisation. Electrical Duty Holders also have a responsibility to ensure that persons carrying out the work are competent to carry out the range of duties/activities required of them.

On completion of the Electrical Duty Holder Workshop, candidates should be able to:

State the relevant statutory and non-statutory regulations (the Health & Safety at Work Act, the Electricity at Work Regulations, Management at Work Regs.) applicable to Electrical activities

State the dangers associated with electricity and moving machinery

Describe the term competency and the assessment of competency

Comply with company procedures and complete associated documentation e.g. permit to work, risk assessments, method statements etc.

Perform safe electrical and mechanical isolations in a range of common industrial scenarios to HSE recommendations for best practice

Logical Approach to Fault Finding and Root Cause Analysis

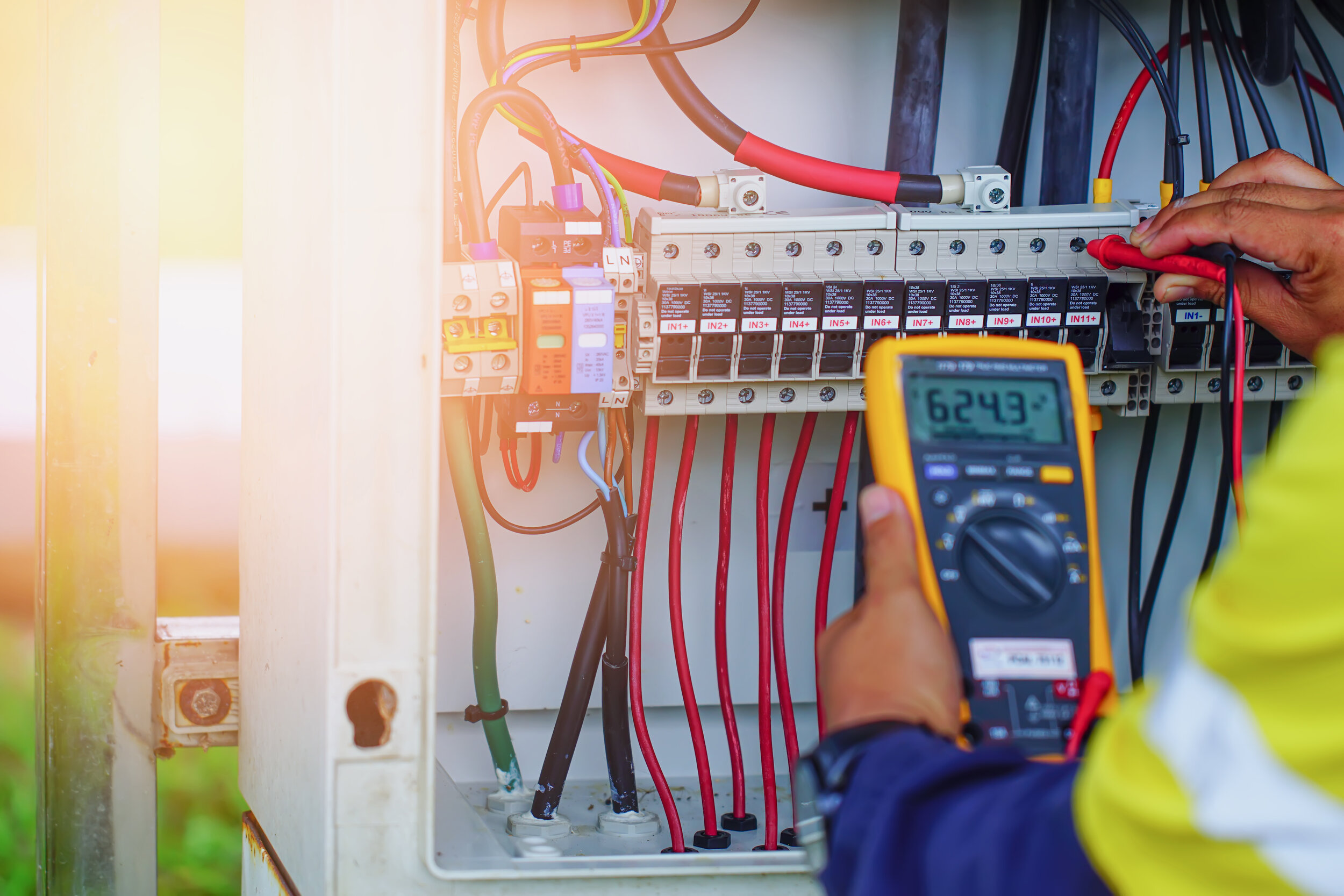

Our City & Guilds accredited Logical Approach to Fault Finding and Root Cause Analysis is a 3 day course which provides technicians with the confidence and ability to identify and fix common faults, reducing downtime.

Logical Approach to Fault Finding and Root Cause Analysis course will cover a series of practical fault finding exercises on pre-prepared rigs with theoretical examples and will focus on:

Recognition and removal of hazards

Differentiation between Methodical and Logical approaches

Application of the six step and half split approach to fault-finding

Correct differentiation between symptoms and causes

Production of Flow charts to aid future fault finding

What is Root Cause Analysis (RCA)?

Why people don’t do use RCA

The categories of root cause

5 stages of an effective RCA

Defining the Problem

Collecting Data

Identifying Possible Causal factors

Identifying the Root Cause

Recommending and Implementing Solutions

5 Whys & Fishbone diagram

Listing and the demonstration of the delegate’s ability to apply logical fault finding techniques to plant and equipment

On completion of this course, delegates will quickly identify the root cause of a fault, using recognised methodologies that provide a logical thought process to common equipment failures.